Single Piece to Full Production Runs

Single Piece to Full Production Runs

COMPUTER CONTROLLED & CUSTOM DESIGNED PARTS MADE WITH HIGH-PRECISION & SPEED.

Our equipment utilizes the latest technologies and software to process raw materials into finished product with high-precision and speed.

Electro-Metrics Corporation has an ISO 9001 certified full-service machine shop that continue to invest in CNC turning centers, bar feeders, machining centers, lathes, and other machine tools. We produce sophisticated machined parts in quantities ranging from a single piece to full production runs of thousands of pieces.

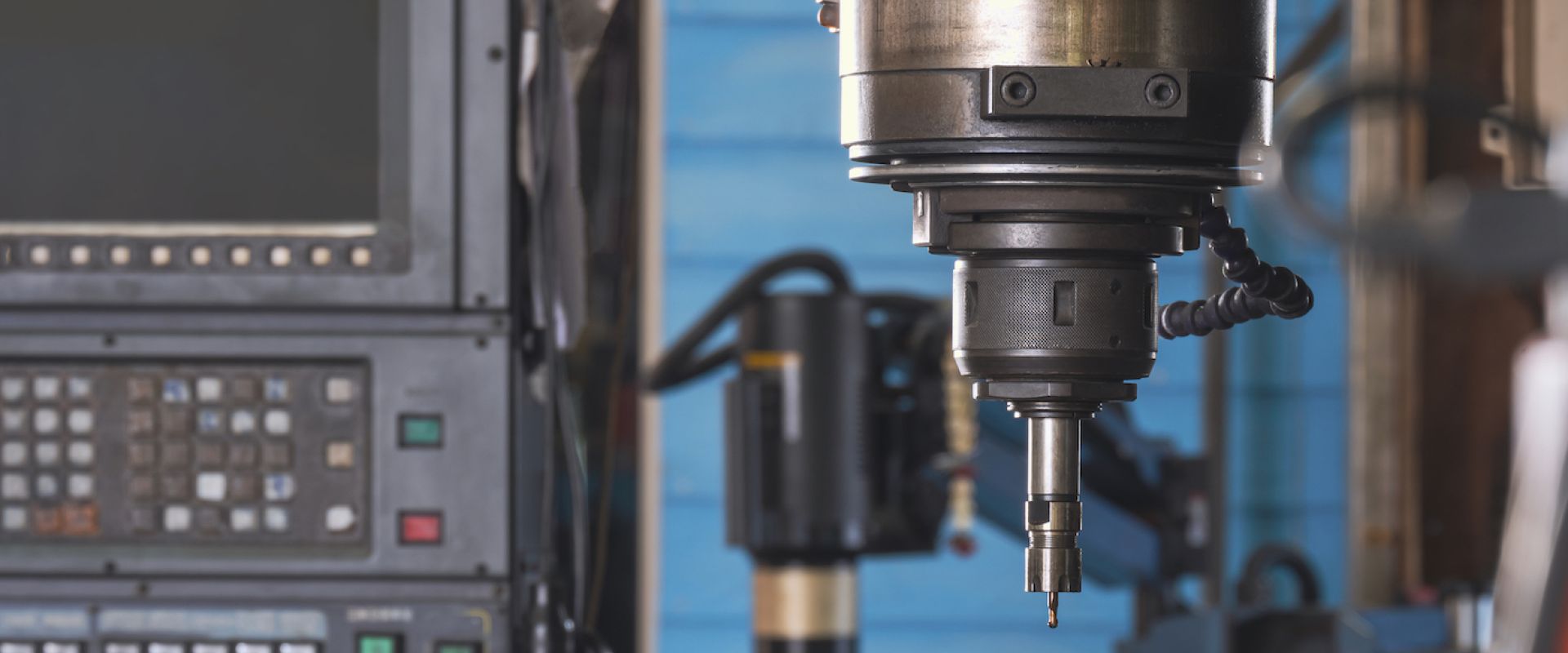

Our Milling Centers

The Mazak 410A with Mazatrol Smart Control

A state-of-the-art CNC milling/turning machine that offers a wide range of advanced features and capabilities, including: multi-axis machining, Mazatrol Smart Control, high-speed machining, automatic tool changer, advanced monitoring, versatility, and a robust construction.

X 35″ | Y 17″ | Z 20″

Spindle Speed: 12,000 rpm

| Specifications | Values | |

|---|---|---|

Capacity | Table Right / Left Table Longitudinal | 35.430in / 900mm |

Spindle | Spindle Taper Maximum Speed Motor Output (5 minute rating) | 40 |

Magazine | Number of Tools | 30 |

Feed Axes | Travel (X Axis) Travel (Y Axis) Travel (Z Axis) | 22.05in / 560mm |

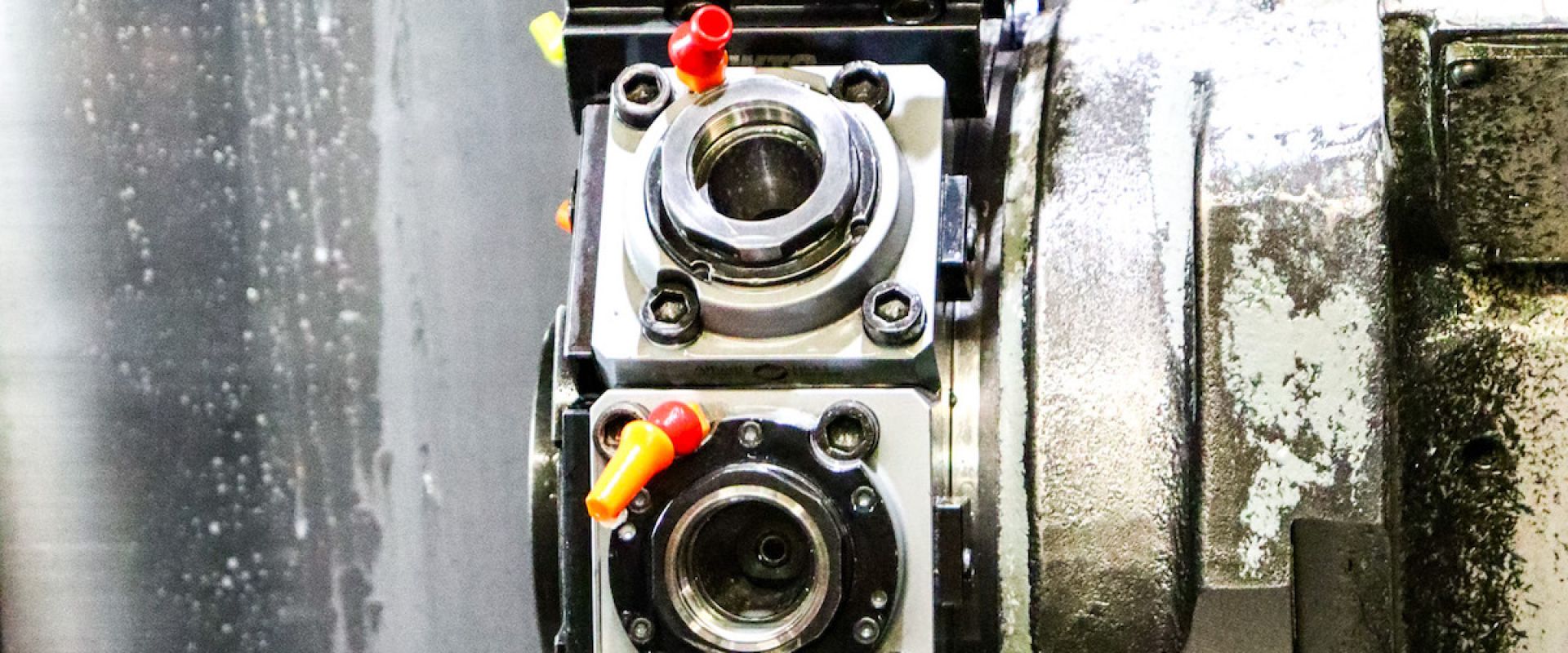

Our Lathes Offer:

-

Swing Over Bead

22.83″

-

Max Turning Diameter

16.14″

-

Spindle Bore

3.58″

-

Spindle Speed

45 – 4,200 RPM

-

Rapid Traverse X, Z

984 / 1181 IPM

-

Tailstock

MT #5

-

Tail Stock Taper

90″ x 72″

-

Swing Over Saddle

18.50″

-

Spindle Nose

A2-8

-

Bar Capacity

3.18″

-

Spindle Motor

40 HP

-

Turret Positions

12 Positions / 1 Turret

-

Spindle Drive Motor

4.72″

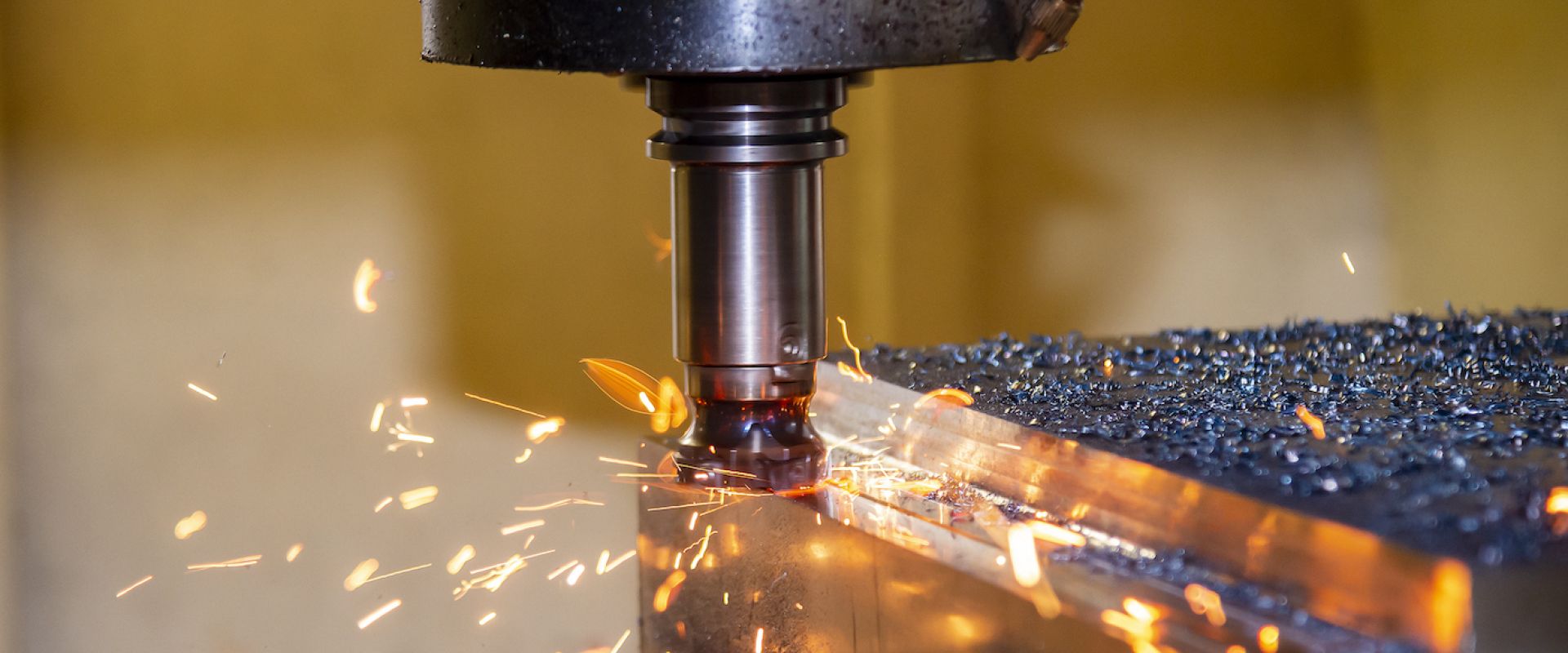

Why CNC Milling / Turning?

Due to the unmatchable benefits they provide, water and laser jet cutting are two of the most prominent cutting technologies used in the fabrication industry.

Various Shapes

CNC milling / turning machines use computer-controlled movements to precisely position and move the cutting tool or workpiece, which allows for the creation of intricate shapes and contours with precision and accuracy.

Cost-Effective

CNC milling / turning machines are highly automated and can produce parts quickly & efficiently with consistent quality & precision.

Minimal Waste

CNC milling / turning machines can be programmed to optimize material usage and reduce waste. This is because the machines can be programmed to cut parts in a way that maximizes material utilization.

Mass Production

CNC milling / turning machines can operate continuously without the need for manual intervention, which means that parts can be produced quickly and efficiently, which reduces production times and increases throughput.

Smooth Finishes

CNC milling / turning machines can produce parts and components with a smooth finish by using the appropriate cutting tool, feed rate, spindle speed, and depth of cut.

Tolerances

CNC milling / turning machines are capable of producing parts with very tight tolerances, typically in the range of a few thousandths of an inch (0.01-0.05mm). Our quality control measures are also implemented to ensure that parts meet the desired dimensional tolerance.